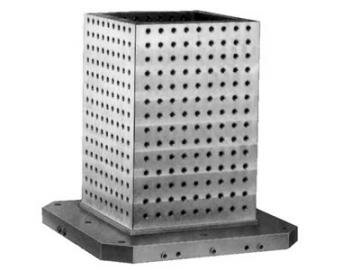

Tooling Blocks

Tooling blocks, which are also referred to as fixture plates, grid blocks, or tombstones. The multipurpose holes (MTP holes) on both the grid style tooling plates and blocks allow for accurate aligning or fastening of other components in a number of locations. This allows for fast and easy modifications to be made to adequately hold a work piece in place. Furthermore, the locating holes on the tooling plates can be used to connect multiple plates of varying sizes together, which allows limitless size combinations to be created.We are manufacturer of various types of tooling blocs which are used for various application in holding of jobwork set for machining.Pallet mounting tooling : Thes tooling blocks also enable simultaneous loading and unloading of multiple fixture plates thereby reducing total set up time.

Key Properties of Tooling Blocks

- Very good surface structure

- High quality

- Easy to machine

- Temperature resistant up to 160ºC

- Excellent dimensional stability

- Low coefficient of thermal expansion

- High impact strength

- Density range from 0.4 to 0.7

Key Advantages Of Tooling Blockss

- Improved speed to market

- Reduced labour times

- Reduced machine times

- Design cycle flexibility

- Reduced development time

- Consistent and repeatable

- Reduced costs

Key Applications

- Prototyping

- Modelling

- Styling

- Metal forming

- Plug assist